Toilet Types

Which toilet type is best for you?

Water Saver

Ultra-Low-Flow (ULF)

High-Efficiency (HET)

Beginning in the late 1990s, however, manufacturers began introducing what are known as “high-efficiency toilets”, or HETs. HETs are defined as having an effective flush volume (see Dual-Flush below) of 1.28 gallons/4.8 litres or less. The HET category includes both single-flush and dual-flush fixtures. The MaP database contains over 3,400 single-flush HET models and 1,900 dual-flush HET models certified to the U.S. EPA WaterSense specification. California, Georgia, Colorado, Texas, Massachusetts, Oregon, Washington D.C., and the city of New York currently prohibit installation of non-HET fixtures (with some exceptions).

Single-Flush

Single-flush toilets have just a single flush volume option. Today, some models flush with as little as 0.8 gallons (3.0 litres), and some flush with as much as 1.6 gallons (6.0 litres). Models certified to WaterSense flush with no more than 1.28 gallons (4.8 litres). Search single-flush here: https://map-testing.com/map-search/

Dual-Flush

Dual-flush HETs let the user select a “full” flush to remove solids or a “reduced” flush to remove liquids only. In the U.S. and Canada, the “full” flush volume cannot exceed 1.6 gallons (6.0 litres) and the “reduced” flush volume cannot exceed 1.1 gallons (4.2 litres). The U.S. EPA’s WaterSense program calculates the “effective” flush volume of dual-flush toilet models as the average of one “full” and two “reduced” flushes, e.g., [1.6 + (2 x 1.1)] / 3 = 1.27 gallons. Many residential studies, however, have found the actual ratio of “reduced” to “full” flushes to be much less than 2:1. To be conservative, the maximum “full” flush of dual-flush toilets qualifying for a MaP PREMIUM designation cannot exceed 1.28 gallon (4.8 litres).

Gravity-Fed

Siphonic

Wash-Down

Wash-down bowls are less common in North America but widely used in Europe and Australia. No siphon is created in wash-down bowls. Rather, the water discharging from the bowl rim ‘pushes’ waste through the trapway into the building drain. Since wash-down bowls do not rely on siphonic action, the diameter of their trapways can be up to 3-inches or larger. While a larger trapway may result in less clogging, washdown bowls typically have a much smaller surface water area (water spot) than siphonic bowls, which can result in a greater occurrence of bowl streaking (AKA, ‘skid marks’).

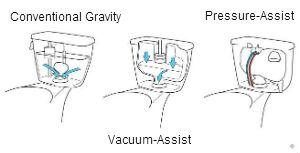

Pressure-Assist

Pressure-assist toilets store water used for flushing in a pressure vessel at the same pressure as the building’s water supply – typically between 40 to 80 psi. Water filling the pressure vessel – which is typically housed inside a traditional-looking vitreous china toilet tank – compresses air contained in the tank. It is the pressure of that compressed air that quickly forces water from the tank into the bowl when the flush lever is pushed. Because water is stored in a pressure tank rather than a vitreous china tank, pressure-assist toilets do not “sweat” even in humid climates. While pressure-assist toilets offer a robust flush action, compared to gravity models they can sometimes be more expensive to purchase, more difficult to repair, and louder.

Round-Front vs. Elongated Bowl Design

Today’s toilets come with either a smaller, round-front bowl or a longer, elongated-front bowl. Round-front bowls were very popular in the 1900s and are still ideal for compact bathroom spaces, such as those frequently found in older homes. Elongated bowls are commonly installed today because they are considered more comfortable for adult use and more hygienic. Plumbing codes require the use of elongated bowls in commercial applications. Search bowl choice here.

Conventional vs. Elevated-Height Bowls (ADA Height)

Children's and Juvenile Toilets

A few manufacturers also market smaller toilets for very young children and juvenile ages, suited to pre-school and day care installations. Go here for the latest list of 37 children’s and juvenile toilets and further information.